The reason is that filleting material (epoxy and woodflour) works better with fiberglass to evenly distribute any sudden loads placed on the seam.

Maintaining a consistent seam gap is also easier to build and fair. We've always recommended a spacer to maintain a consistent gap. The problem is that just putting a spacer or shim in the seam isn't always easy because the spacers twist or fall out.

Well here's a way to solve that:

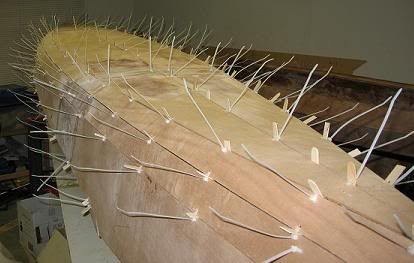

1) Get some tongue depressors (craft sticks). I like using the wide ones because they are only about 3mm thick. Drill 2 holes about 1/2" apart, then one in the middle to make a slot.

2) Stitch the hull with the stitches going right through the slots.

3) Adjust the spacers so you have a consistent gap. What's also nice about this is you can pull the stitches tight.